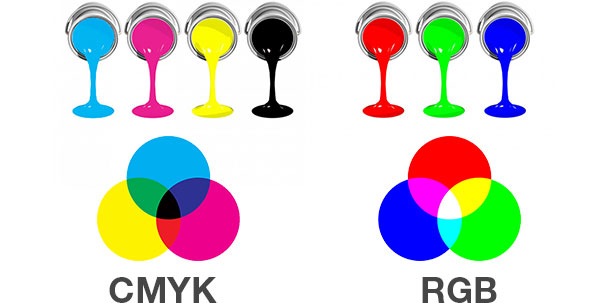

Printing: Inks

CMYK (Full Color)

Process color, or CMYK color, uses four colors, which give the name its initials: cyan, magenta, yellow, and black. These four colors work together to form all other colors that are used in printing by using various color saturations. Process color is the most commonly used type in the packaging and printing industry.

Pantone Matching System color (PMS)

PMS color, or Pantone Matching System color, is frequently used for printing spot colors, as these are printed with unique ink. The color is specified based on its pantone number or name within a color chart. It allows the colors to appear exactly as intended once printed instead of how they appear on a computer screen.

Printing: Coating

Aqueous

The aqueous coating method is a clear and very quick drying water based coat that is used to help protect surfaces. This protective coating also help reduce fingerprints and dirt from sticking to the surface.

Glossy UV

Creates the highest printable overall gloss coating. Gloss UV coating is premium coating that makes pictures really stand out. It really enhances color contrast and makes those vibrant colors pop out, more so than regular gloss. As you can see from the picture above

Matte UV

Matte UV gives the printed box a non-glossy, smooth even surface free from shine. This matte finish on the printed box adds to the feeling of luxury. It is the most popular finish used in the luxury packaging of the cosmetics and jewelry products and etc when the seller wants to impart a luxury quality feel to the potential customers

Soft Touch Coating

This coating creates a velvety texture. The paper becomes "soft" to the touch and increases the tactile appeal. This stylish finish allows a printed piece to stand out from others by creating a subtly plush texture that encourages touch and engagement. The best part is that this unique texture does not diminish color or quality. Plus, it is environmentally friendly

Additional Finishing

Additional Cut Out

Addition cuts, holes, slits or specific shape and dimensions of your packaging, can be added to any custom box.

Window Patching

A plastic film is added on a folding carton packaging serving a dual purpose. It teases the product by making some of it visible and can also it prevent product from coming into contact with the carton.

Embossing

The image is molded in embossing So that it is raised in relief. This option lets you create sculpted designs and text on the surface. Molding is achieved by pressing the material to embossed to create a 3D texture.

Debossing

Debossing is the opposite of embossing, where the pressure is applied down on to the outside of the box to create debossing.

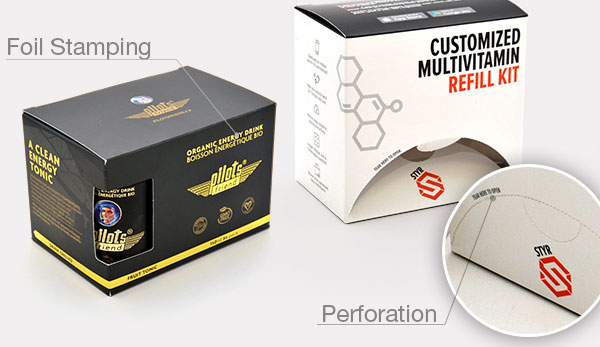

Foil Stamping

Application of pigment or metallic foil, often gold or silver to paper where a heated die is stamped onto the foil, making it adhere to the surface leaving the design of the die on the paper.

Perforation

Perforation is done by assembling a sequence of small holes that serve the purpose of easily being removed. For example, a box flap could have perforation along the edge so that the flap can be removed hassle free.

Let’s begin sourcing your custom packaging.

From concept to production, it’s never been simpler.

Proudly Printed in Canada

Proudly Printed in Canada