- Dieline Design

- Prepressing

- Die Making

- Printing

- Cutting & Creasing

- Waste Stripping & Recycling

- Other Processes

- Gluing

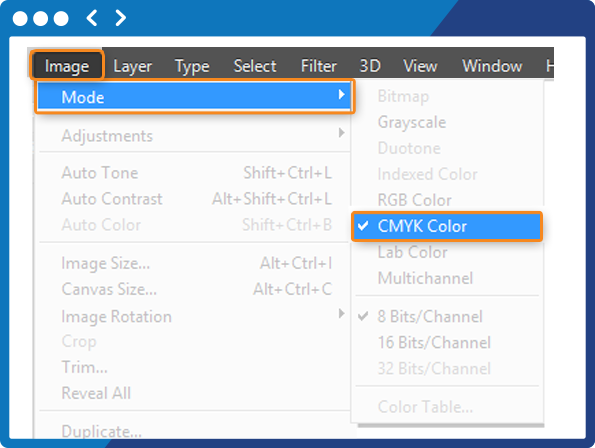

CMYK color is cyan, magenta, yellow and black ink. Each color prints from a separate plate as dots and screens in layers to create colors. CMYK is also known as process color or four color printing.

PMS stands for Pantone Matching System. This system was developed in the early 1960s and is internationally recognized and used in print, graphic, fashion and interior design. PMS colors are assigned numbers and formulas for ink mixing. A palette of 14 basic colors are used to mix inks according to the formulas. The color PMS 285 printed in two parts of the world on the same paper will match due to the consistency of the formulas. Printers can order the colors by numbers or use the formula to mix the ink color themselves.

CMYK will always be the standard in most color printing, however PMS offers an expanded horizon of choices.

After designing a document comes prepress. It is the process of preparing digital files for the printing press making them ready for printing (pre > before and press > printing on a printing press). Prepress or make-ready tasks will vary depending on file complexity and printing method but some may include:

- double-checking fonts

- making sure graphics are in the right format

- preparing camera ready artwork

- creating color separations,

- adding crop marks

- trapping (done to prevent color gaps when colors touch in a layout)

- imposition (putting pages in the right order for printing)

- producing prepress proofs

- obtaining film for creating printing plates

Print Coatings: Understanding UV Coating,

Spot Varnish, and Aqueous Coating

Before ordering

any type of custom packaging, it helps to be aware of the

various print coatings to choose from. Just like the rest of

your packaging, you can completely customize the print

coating to meet your specific needs.

The various

types of print coatings that you choose from include:

- Aqueous Coating

- Varnish

- UV Coating

- Soft Touch Coating

Aqueous coating refers to a fast-drying and water-based coating that is clear in color and designed to protect various printed pieces. This particular coating will give you a matte or high-gloss surface, which is able to deter both fingerprints and dirt. The coating will also improve the durability of mailed pieces, such as postcards, during their trip through the mail system as well as protect business cards that go in a wallet. In addition, it adds a nice finishing touch to presentation folders, catalog covers, and brochures. An aqueous coating is better at resisting scuffs compared with varnish, and it is usually the last step on the printing press and applied over the entire piece. The water base also makes for a greener coating compared with UV coatings or varnishes.

Varnish is a type of clear ink and may appear in matte, satin, or gloss. One type, a flood varnish, will cover the whole printed page, adding sheen and protection. Another option, spot varnish, lets you highlight particular areas within a printed piece, adding depth and shine to specific elements, such as the image or logo. Varnishes are applied on-press, but may be applied (via inks) to only certain parts (such as spot varnish) and are heavier-bodied. Artwork is needed for spot varnishes, so a plate needs to be created first.

A UV coating is cured via ultraviolet light exposure, letting it dry quickly while hardening the coating. This coating provides the highest amount of gloss, but it might crack if it is scored or folded, depending on the hardness and thickness of the coating. Some people see UV coatings as too shiny. These can be applied as floods (over the entire sheet) or spot coatings, as well as either on or off the press. UV compatible inks need to be used with a sheet that will use UV coating, and these sheets can’t be foil stamped. You must emboss after the coating process is done if you would like to do any embossing on the printed product.

Soft touch coating will make the paper develop a texture that is “soft” and velvety when touched as well as increases its tactile appeal. This particular coating will also give a softer feel and look to printed materials compared with UV or aqueous coatings. At the same time, it still manages to create a barrier that is resistant to fingerprints. Soft touch coating also dries quickly, making the printing process shorter, and as a bonus, it is also ecofriendly and does not yellow over time. Many people associate the soft touch coating method with the words “sophisticated” and “luxurious” due to the results and ecofriendly process.

Rush Orders: 5 or 10 business days from receipt of the CONFIRM and APPROVE dieline and artwork.(Not available)

Turn Around Times for rush orders require prompt approval of dieline and artwork / proofs. Failure to approve dieline and artwork due to changes or lack of response to email or phone calls will delay your order.

However the price wouldn't be version qty times per version total, more close to one version total with additional charge over it, for orders in such cases please contact our sales representative through toll free number 1-866-836-9769 or email to sales@soopak.com for accurate quotation.

The best way to meet your particular specifications for unique packaging is to work closely with a printing company and its design team. During the process, you will submit various drafts to help turn the vision into reality through the work of your team. If you want to find out more about custom options that you will find on box orders, visit www.soopak.com.

You have multiple designs to select from for gift boxes. You can customize the box with a logo, a creative shape, or by adding a handle. Your goal should be to ensure that the gifts stand out, enticing people so they want to learn more about what is within. Stopping by www.soopak.com can show you the highest-quality gift boxes for your special events.

In some cases, a client may send an example of the packaging to the print company. The company would then take apart the sent package to locate graphics and tucks and take measurements. When there is a product, but no packaging, the measurements are instead taken for the actual product with wrapped paper added to estimate size.

After the measurements, Adobe Illustrator is used to create the die lines, following specific design standards. You would ideally test a hard copy of your created die line to ensure it works with the product. After that, it is time to make hard copy prototypes using such materials as heavyweight paper. After the prototype is checked for such factors as sturdiness, the packaging can be prepared for the shelves.

You can find templates in almost any shape and size, and these include everything from door hangers to pyramid-shaped boxes. Templates are sometimes listed based on the quantity of panels they contain, as this varies based on needs. Accordion templates are popular, as they can hold information within a large number of panels. Tray card templates, on the other hand, are more popular with compact disc packaging.

Printing templates help customers easily customize their packaging. You can usually find them for free, and they are easy to open with Adobe Illustrator, which is where you would make any edits. Templates may also be customized within Adobe InDesign, Adobe PDF, Microsoft Word, or QuarkXPress.

After you download the template, you can add your content to it via your favorite program. This template will be crucial for determining the content and layout of your page as the consumer will view it. The fact that the process is easy and fast means you do not always need to hire a professional graphic designer and will be able to create a final product within mere minutes.

Process color, or CMYK color, uses four colors, which give the name its initials: cyan, magenta, yellow, and black. These four colors work together to form all other colors that are used in printing by using various color saturations. Process color is the most commonly used type in the packaging and printing industry.

Process color, or CMYK color, uses four colors, which give the name its initials: cyan, magenta, yellow, and black. These four colors work together to form all other colors that are used in printing by using various color saturations. Process color is the most commonly used type in the packaging and printing industry.

Another benefit of eco-friendly packaging is that it uses soy ink, which is better for the planet. This type of ink also offers brighter colors, which are not possible to get with petroleum-based inks. The largest benefit to the planet, however, is that soy ink has very low levels of volatile organic compounds (or VOCs), which are harmful to the environment.

You can customize a countertop display box to serve as a ballot box and find options that include pegs, letting them display individual items, such as key chains. Some boxes may contain single sections to hold smaller or thinner items, such as brochures. Countertop displays are a powerful method of drawing customers in when they make their purchase, which is the critical point.

You should opt for a retail packaging box design and style that instantly engages your consumer. This will give you the desired end result of them leaving with your product.

We can help you reach those goals. Our production team is knowledgeable and experienced with packaging and printing, allowing them to guide you every step of the way so you can produce a polished final package.

- soopak.com provide 3 main categories that customers

could choose their ideal packaging solution from.

By Box Style: lists all standard box structure that soopak produces, if you want to make your choice on style of the box to meet your packaging needs, this is where you should go

* Products under this category come with Custom dieline design. - By Industries is a selection

of best practice packaging solution provided by SoOPak

structure designer, technical sales specialist and analysis

of soopak client’s choice, which ensures you a hassle

free purchasing experience.

* Products under this category come with FREE dieline design. - Custom Style is a complete tailored packaging solution for your packaging, our experienced structure designer will work with you till your brilliant ideas convert to a real folding carton, as we believe your ideas deserves it.

- Get a quotation in By Box Style & ByIndustries: once you chose a product page under this category, input product options like dimension; color; coating¦ the price will be changing while you are featuring them, till you input the last one qty, you've finished the quotation process and should be able to see the lot price with per unit price as well.

- There is one thing special while you are getting quatation from Custom Style, the dimension input option only shows Length & Width (unlike all other categories shows Length Width & Height), this is because custom style box may not erect into a cube but special shape, thus on this very product page custom style the length and width represents the only 2 dimension of the flat dieline design of this custom style box.

If you like the quotation, please added it into your shopping cart to reserve this quotation, which makes placing order easier in soon furfure. (please make sure you are logged in)

You like the quotation, let's get the ball rolling, to have a

folding carton made, normally there are 2 elements before

production: dieline & artwork (unless your packaging is

plain carton, that case dieline is the only thing we need.)

First thing would be dieline design,

the structure of the box.

- To get a dieline design please go to Design, there are 2 options you could choose from, standard dieline design & custom dieline design,

- Standard dieline design Free: In Step 1, if you found your ideal box style in By Box Style or By Industries product page, please input that product ID in this page, along with dimension, paper stock and if you need prototype box, then add to cart and proceed to check out. A dieline design file will be sent to you through Email and 2 prototype boxes (if applicable) will be shipped to you within 24 hrs. If you confirm the dieline design, then we can move to artwork design

- Custom dieline design: If you didn't find your ideal box in By Box Style or By Industries, then we could design the box from scratch custom dieline design, to ensure our structure designer acquires enough details of your idea, we'll need detailed dieline description & images in:

- Box style: if the main structure is similar to any of our standard box style, please list the it's product ID; if not please provide an image or drawing of how the box looks.

- Detailed feature: tear open; cut out; lock; insert ¦

- Dimensional figure: L; W; H; radius angle; diameter; cut out position¦

- You’ve had the dieine for your box as you have ordered the same structure box before, then we can move to artwork design.

- You've had the dieine for your box as you have ordered the same structure box before, then we can move to artwork design.

Now both dieline and artwork is ready, you are one step away from realizing your packaging design into real box Place Order

- If you have reserved your quotation, you could tune to shopping cart, find the quotation and click edit to get back to product page with all prefix settings and upload your artwork there, then proceed to check out.

- If you didn't reserve quotation, tune to the product page according to product ID, fill out all the same setting and upload artwork there then proceed to check out.

Now your order is in soopak production list, our prepress department will process your artwork to press ready file rand send it to you to confirm, after it's confirmed, we guarantee your order to be ready for shipping in 10 business days.

Adobe Illustrator AI

Press Quality or Hight Quality Print PDF

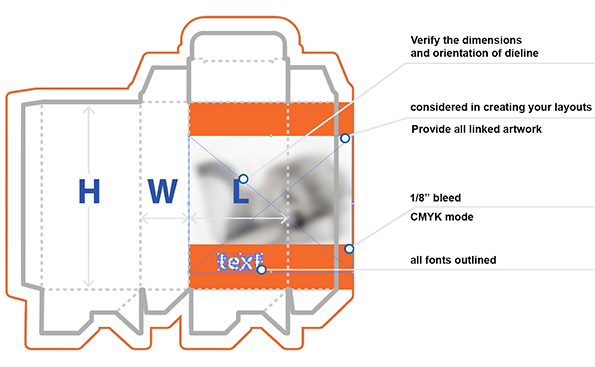

- Verify the dimensions and orientation of dieline for which you are creating your artwork.

- Check to see if there are any “safe viewable areas”, cut-outs, glue area, crease (folding line) that must be considered in creating your layouts.

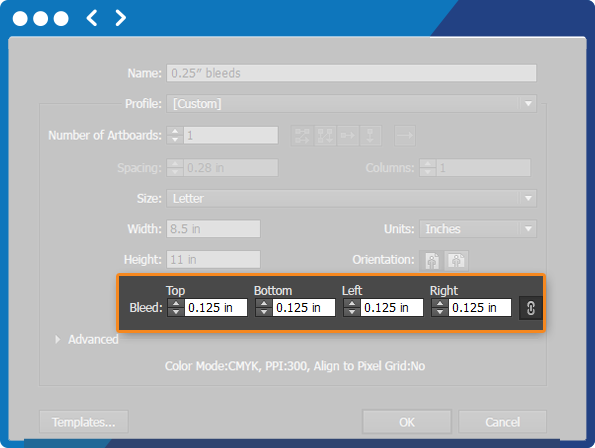

- Include “1/8” bleed.

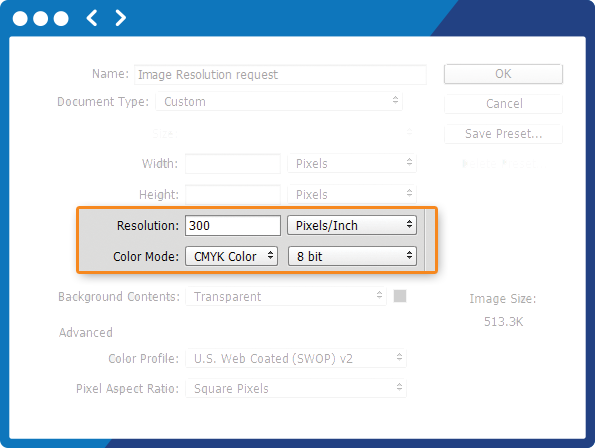

- Create files in CMYK mode.

- Provide all fonts or all fonts outlined.

- Provide all linked artwork DO NOT embed images.

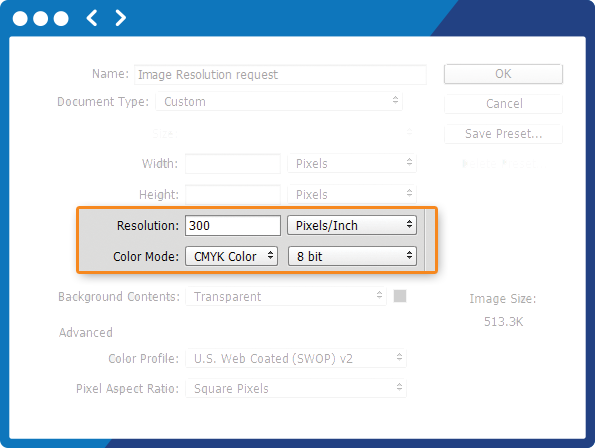

- Resolution should be a minimum of 150 DPI to a maximum of 300 DPI at the final (100%) size.

- Never use low-resolution images (i.e. screenshots, low-resolution web images, etc.)

- If a Hard Copy Colour Proof has not been requested (additional charge), we would send press digital proof file through email.

- If Hard Copy Colour proof is required, we would need PMS Colors to be specified or physical proofs or previously printed boxes are provided to match.

- Hard Copy Colour Proof: Press ready file printed over proof paper plus Color Drawdown

- Colour Drawdown: PMS Colour ink applied over ordered stock paper, coated and uncoated

No.

SoOPAK accepts

print-ready files in any of the following formats:

ai, pdf

In other

words, SoOPAK accepts print-ready files saved from the

following design software programs: Adobe Photoshop® CS,

Adobe Illustrator® CS, Adobe InDesign® CS

Adobe Illustrator AI

Press Quality or Hight Quality Print PDF

Resolution also known as DPI (Dots

Per Inch) can be described as the number of dots that fit

horizontally and vertically into a one-inch space. Generally,

the more dots per inch, the more detail captured and the

sharper the resulting image.

For an image to print

properly, the image must be at least 300 dots

per inch (dpi) at the final output size. If your file is not

300 dpi, you cannot simply increase the dpi from a low

resolution to a higher one by increasing the DPI in your

imaging program.

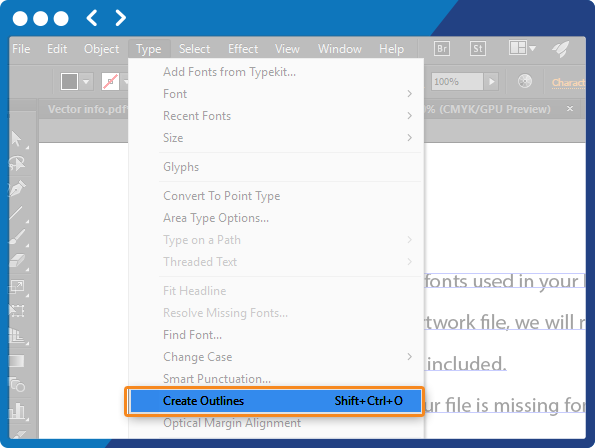

It is important that you supply all fonts used in your

layout. If you do not supply fonts in your artwork file, we

will request that you resubmit your files with fonts

included.

If you have vector artwork and your file

is missing fonts, you can open your file in Illustrator,

select "Create Outlines", save

your fonts, re-save your artwork file, and then upload it.

If you have artwork that is rasterized, you can open your

file in Photoshop and select "Flatten the Layers",

re-save your artwork file, and then upload it.

Please do not submit your fonts seperately from your file

because it is critical that we receive your print-ready file

with fonts included to avoid any printing issues.

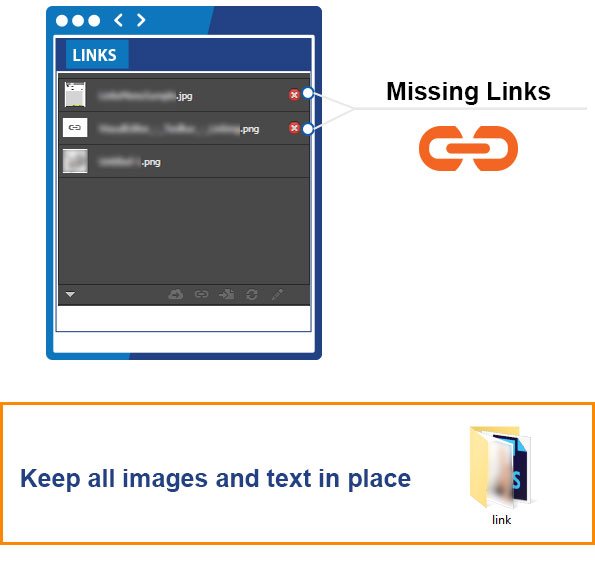

Please EMBED all the image in your file.

If

your file is missing the images you desire, you should

re-save your file properly so that the images will not drop

out during printing.

We do not normally accept

images by themselves. The only exception is if you engage one

of our graphic designers to help you with your project.

Otherwise, you must place all images in your artwork and make

sure to save your files properly. Please refer to your

software program manual for more information on how to save

your files properly.

Vector-based software programs

such as Illustrator or InDesign have a tendency of image

dropping out when transparency effects are being used.

If you are using Photoshop, you should flatten all layers

before saving to keep all images and text in place.

Proudly Printed in Canada

Proudly Printed in Canada